Flashing and sheet metal 05 17 part 1 general 1 1 references 1 2 general requirements 1 3 submittals 1 4 miscellaneous requirements 1 4 1 product data 1 4 2 finish samples 1 4 3 operation and maintenance data 1 5 delivery handling and storage part 2 products 2 1 recycled content 2 2 materials 2 2 1 exposed sheet metal items.

Sheet metal flashing and trim specification.

Csi divisions division 07 07 60 00 flashing and sheet metal manufacturers of flashing and sheet metal browse companies that make flashing and sheet metal and view and download their free cad details revit bim files specifications and other content relating to flashing and sheet metal as well as other product information formated for the.

Sheet metal flashing and trim 07620 3 b.

1 delete or edit text in if not applicable to project.

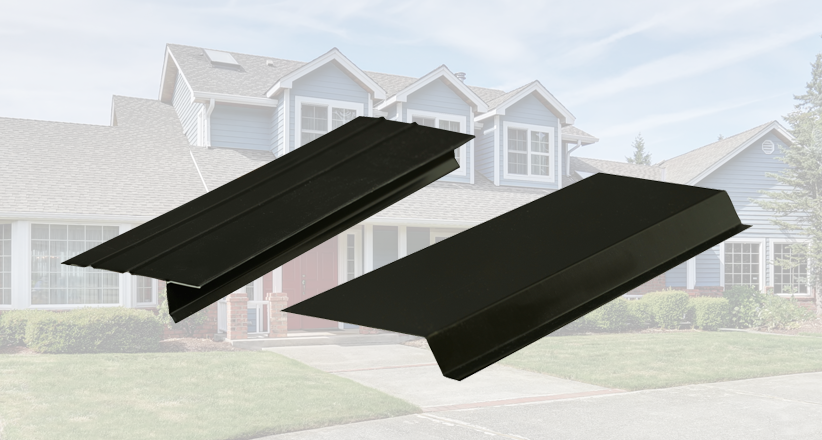

Capabilities include all traditional sheet metal flashing used in conjunction with slate roof systems standing seam systems and fine tile and shingle systems.

Masterspec technical specifications division 07 thermal and moisture protection.

Stack materials on platforms or pallets covered with suitable weathertight and ventilated covering.

Astm a653 a653m with g90 z275 zinc coating or az50 coating.

Minimum 0 02 inch 0 6 mm thick base metal shop pre coated with pvdf coating.

Browse companies that make sheet metal flashing and trim and view and download their free cad details revit bim files specifications and other content relating to sheet metal flashing and trim as well as other product information formated for the architectural community.

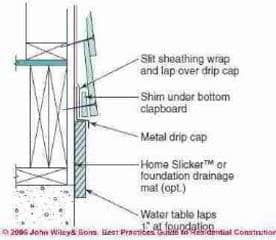

Formed sheet metal work for flashing and insulated expansion joint covers are specified in this section.

Download technical datasheets and 3 part specifications for flashing and sheet metal with smartbuilding index the resource construction industry professionals rely on to help with critical decision making csi masferformat division 07 60 00.

Miter corners seal and solder or weld watertight.

Brief product specification coppercraft offers a full line of sheet metal flashing and trim products allowing designers to specify a complete sheet metal package.

Securing sheet metal flashing and trim including pattern of seams termination points fixed points expansion joints expansion joint covers edge conditions special conditions and connections to adjoining work.

Sheet metal flashing and trim 076200 7 cleats to support edge of external leg and drill elongated holes for fasteners on interior leg.

Section 07 60 00flashing and sheet metal.

Completed sheet metal flashing and trim that does not rattle leak or loosen and will remain watertight.

07 60 00 3.