Circular saw 2 x research source slower than angle grinder but follow same step 2 pre drill holes on the ridges.

Sheet metal roofing installation.

We not only provide maintenance and installation of both modern and time tested roofing systems but also offer plenty of tips backed by years of solid experience to inform clients about the most practical roofing systems for a home or business in.

A good metal roof starts with the right materials.

Diy metal roofing installations will require the following materials.

Steel panels rectangles or squares staple gun.

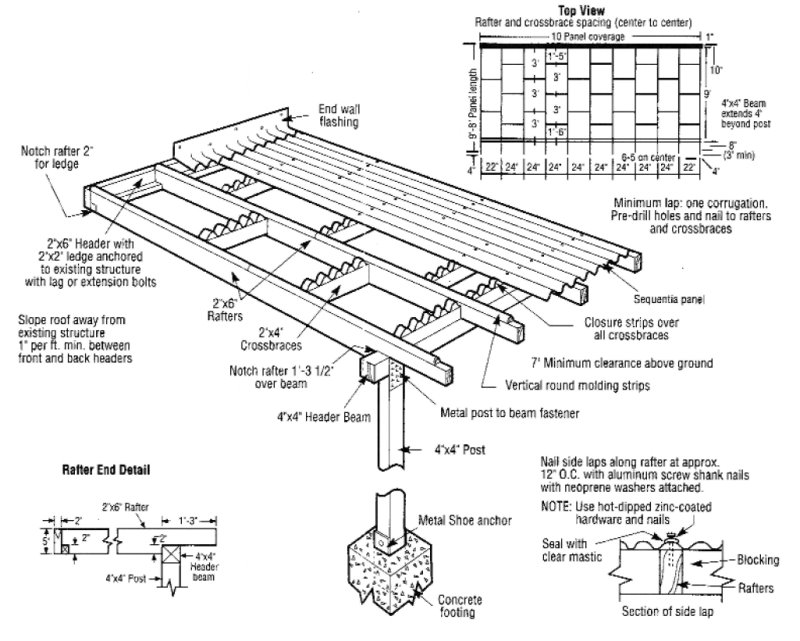

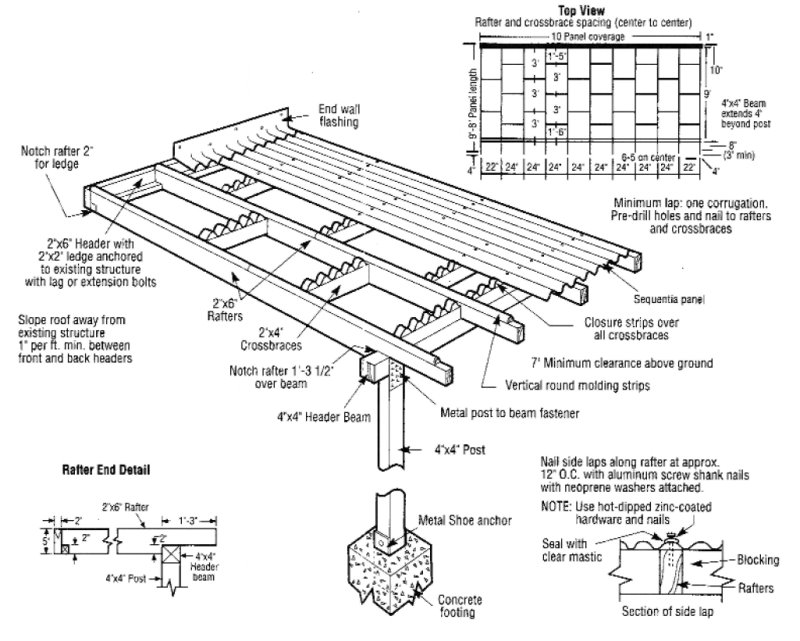

Install the roofing screws vertically along each rib in the panel.

Drill and full assortment of drill bits.

5install metal panels or shingles.

Use your neoprene washer head screws to secure the metal to the sheathing.

Most panels come up to 32 feet 9 8 m in length.

1 inch roofing nails.

Laying metal sheets in runs is normally the best way to achieve this and we recommend by starting at the eaves and in the corner away from the direction of the prevailing wind if it s a single sheet run.

Be sure the larger edge is laid so that the small edge of the next panel will overlap it.

Wear hearing and eye protection.

Angle grinder 1 x research source the fastest option.

Some panels have pre drilled holes.

Paint or prime cut edges to prevent rust.

Take care the first piece is aligned precisely perpendicular square to the edge.

At cladco we want to ensure that once you ve purchased our roofing sheets that you know exactly how to lay roof sheets tile sheets and more in the preferred way.

Ev sheet metal seamless gutters understands that installing a new roof is an important decision.

Align the first metal roofing panel so that it overlaps the edging by 1 2 to 3 4 of an inch and is square to the roof line.

Allow for a minimum of 18 inches 46 cm if you need to lap to complete the run.

Step 1 cut the panels to the desired length.

If yours do not.